In the world of frozen treats, IQF (Individually Quick Frozen) smoothies stand out as a delightful blend of convenience and nutrition. From the moment the frozen fruits are carefully selected to the final packaging, each step in the production process plays a crucial role in ensuring that the end product is nothing short of perfection. Let’s take a closer look at the steps involved in bringing Life Smoothies products to life.

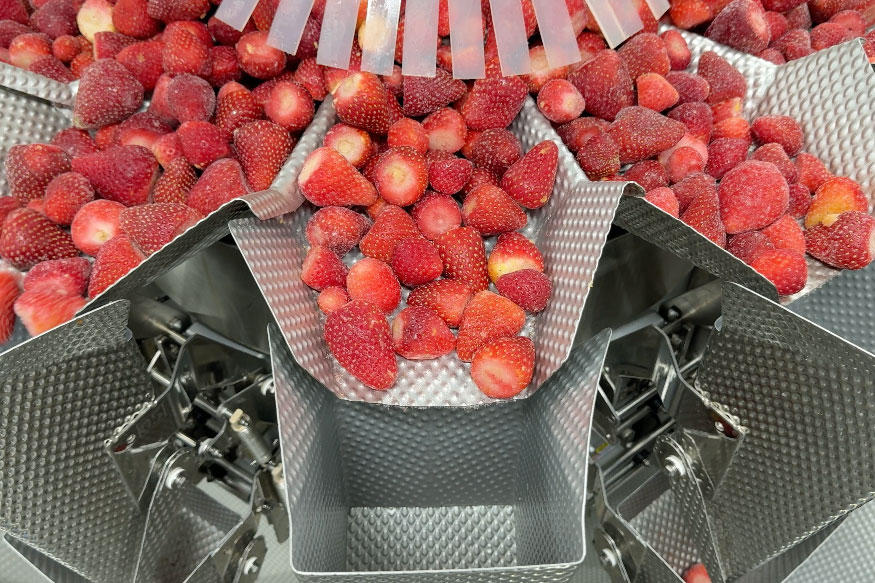

Step 1: Frosty Beginnings – Loading IQF fruits on Upper Storage Funnel

The premium IQF fruits are loaded into the upper storage funnel, ready to embark on their transformation into delicious smoothies.

Step 2: Down the Funnel – Dropping Fruits on the Discharge Funnel

Once the fruits are in place, they make their way down the discharge funnel, where they are gently released into the next stage of the process. This step ensures a smooth and continuous flow of ingredients, setting the stage for the magic that is about to unfold.

Step 3: Mixing Magic – IQF Frozen Fruits Mix in Conveyor Bowls

As the fruits journey along the conveyor belt, they are mixed to create the perfect blend of flavours. Whether it’s our signature Mango Paradise smoothie or our Raspberry Love smoothie, precision is key as each fruit is evenly distributed to ensure consistency in every sip.

Step 4: Label Printing

With the smoothie mixture nearing completion, attention turns to the final details. Labels are printed with care, showcasing not just the name of the smoothie but also important nutritional information and ingredients. This step adds a touch of professionalism and ensures that consumers can make informed choices about their purchases.

Step 5: Sealing in Freshness – Packaging the Frozen Smoothies into Sachets

As the smoothies are packaged into individual sachets, special care is taken to seal in freshness. Each sachet is carefully sealed to prevent freezer burn and preserve the vibrant flavours of the fruits within. This step ensures that every sip is as refreshing as the first, even after being stored in the freezer.

Step 6: Quality Assurance – Passing Through the Metal Detector and Weigher

Before the smoothies are deemed ready for distribution, they undergo rigorous quality checks. Passing through a metal detector ensures that no foreign objects are present, while a weigher ensures that each sachet contains the perfect portion of smoothie goodness. This commitment to quality guarantees that every smoothie that leaves the facility meets the highest standards of excellence.

Step 7: Ready for the World – Sealed Inside a Box and Ready for Delivery

With quality assured, the smoothies are sealed inside boxes, ready to embark on their journey to businesses around the world. Whether enjoyed as a quick breakfast on the go or a refreshing snack after a workout, our smoothies are sure to delight taste buds and nourish bodies wherever they go.

From loading the fruits to the final sealing inside boxes, every stage of the process is infused with care and attention to detail. So the next time you reach for a frozen smoothie, take a moment to appreciate the journey it took to reach your glass and savour every sip of its deliciousness.

For inquiries and orders, contact our sales team at [email protected] or visit our website at www.lifesmoothies.ae